PROFESSIONAL CASTING RESINS FOR INDUSTRY

epple reactive casting resins offer components reliable protection from environmental impact and damage! Reliable, stable and permanent. A casting resin is a reactive resin which particularly protects electronic components: from mechanical damage, weather impact, chemical impact, dust and moisture. In addition, casting resins increase the mechanical stability of sensors, capacitators or complete regulating units and control devices. Where appropriate, they also improve heat dissipation.

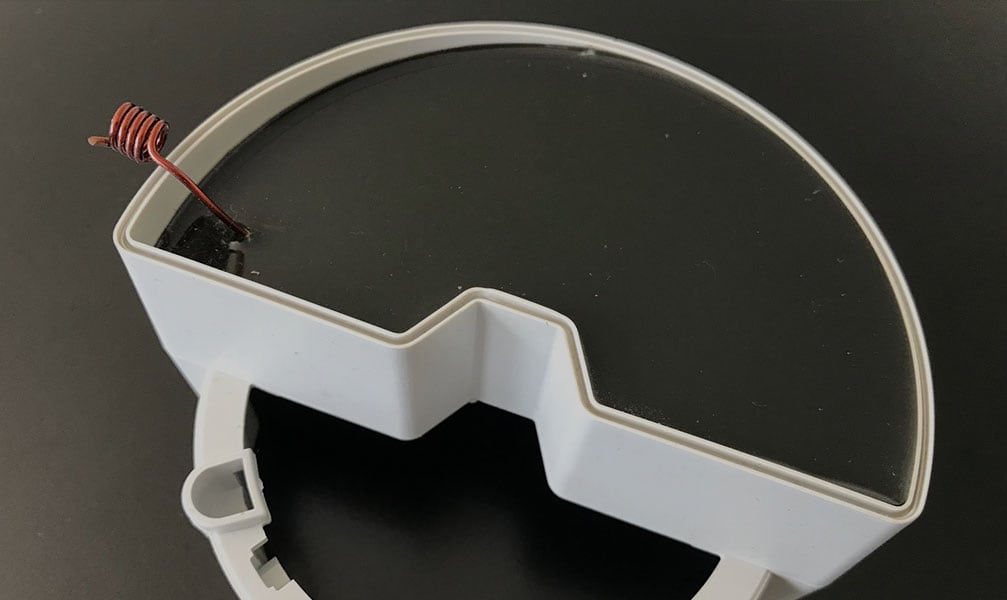

POLYURETHANE CASTING RESIN epple 06872

Moulding of different electronic components

- Resists fluctuations from -40°C to +130°C

- Low shrinkage during curing

- High flexibility to withstand mechanical stresses

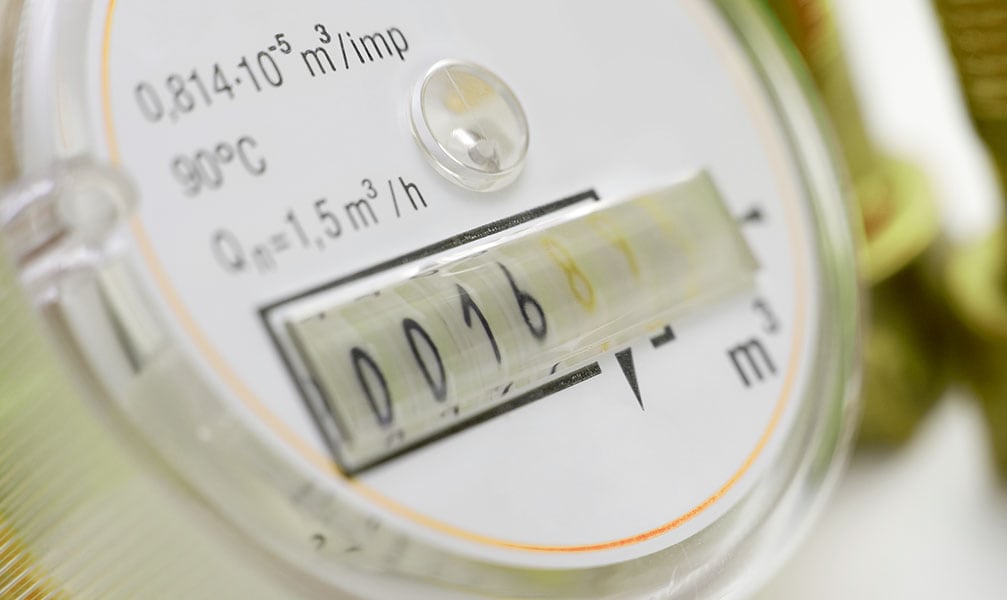

POLYURETHANE CASTING RESIN epple 07144

Moulding of: control electronics for different motors, water meters

- Resists fluctuations from -40°C to +80°C

- Oil-resistant

- RME

- Flexible

- Good ventilation

- Suitable for manual processing

INDUSTRIAL CASTING RESINS TO MEET ALL DEMANDS

Depending on the type of application, we offer casting resins for high or low temperatures, for moist or dry materials and environments. epple casting resins are available as one- or two-component resins, either on an epoxy or polyurethane base.

Depending on the type and area of application, available with higher or lower viscosity, shorter or longer curing time. So you can choose, together with our application technology and from a variety of possibilities, the material which meets your requirements.

Typical questions concerning later uses of the cured casting resin:

- Must it be hard or soft for the application?

- Should the cured resin withstand a thermal stress?

- Is a water or solvent stress expected?

- How good must the electrical insulation properties be?

- Should the casting resin be flexible, is a bending strain or torsional stress expected?

... and its previous processing:

- What materials and components are to be moulded?

- Must the casting resin flow into narrow cracks or scratches?

- Should the casting resin enclose protruding components?

- What temperature increase can the components withstand?

- Should the casting resin be mixed manually or processed by machine?

- How long must the process time be?

We seek a close personal dialogue with our customers. Market-orientated, we develop today the products for tomorrow. Do not hesitate to contact us. We shall find your optimal solution. Competence connects!