Our quality control offers you

Diligent inspection of incoming goods and raw materials as well as extensive goods despatch controls ensure the maintenance of the high quality both we and our customers demand.

We monitor:

- Viscosity

- Solid content

- Density

- Ignition loss

- Refraction

- Colour

- Pot life

- Hardness

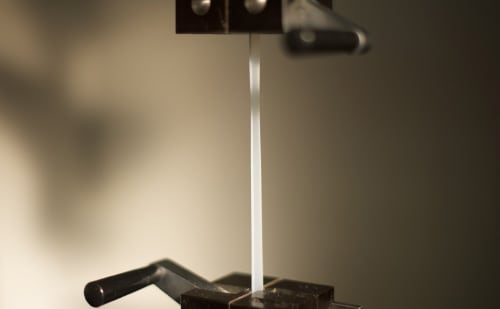

- Tensile strength, ultimate elongation

- Moisture content

- Bonding strength

- Particle size / grinding fineness

- pH value

- Initial and final curing

- Penetration

- Resistance to chemicals, cold, heat

- NCO content (isocyanate content)

and many more customer- and product-specific tests.

Measurements and tests of all kinds

epple has a wide range of measuring instruments and equipment which enable comprehensive examination of materials according to corresponding norms. For example testing adhesive strengths with a tensile test (DIN EN 26922), a shear tension test (DIN EN 1465), a floating roller peel test (DIN EN 1464), a T-peel test (DIN EN 53282), determining creep behaviour, creep strength, surface adhesion. These are just a few examples of the many quality control tests we carry out for customers.

We also offer customisedtesting setups. Ask for further details.